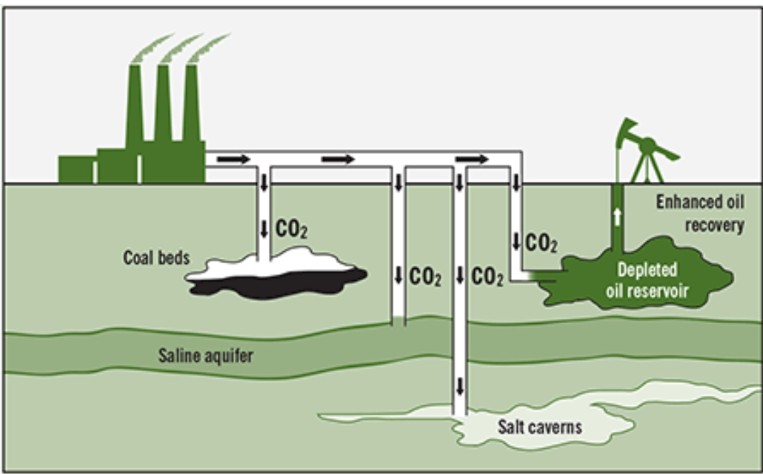

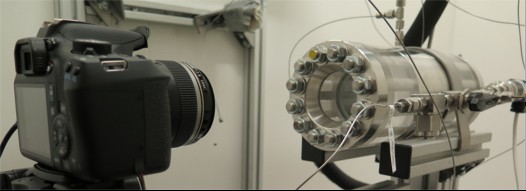

Corinth Pipeworks, a leading manufacturer of high-performance steel pipes for the energy sector, announces a significant milestone in the advancement of carbon capture and storage (CCS) technologies. In collaboration with Norway’s renowned Institute for Energy Technology (IFE), the company has launched a rigorous CO₂ testing program to evaluate the performance of its pipe materials and welds under extreme conditions.

This strategic initiative underscores Corinth Pipeworks’ commitment to innovation, safety, and sustainability in the evolving energy landscape. As governments and industries intensify efforts to combat climate change, reliable CCS infrastructure is critical to enabling the secure and long-term transportation of captured carbon dioxide.

Corinth Pipeworks already plays a pivotal role in shaping global CCS deployment, having secured and delivered key pipeline projects including the Porthos CCS project in the Netherlands, BP's Net Zero Teesside Power (NZT Power) and Northern Endurance Partnership (NEP) in the UK, the recently awarded HyNet CO₂ Pipeline (UK), as well as multiple CCS projects in the United States.

These projects not only demonstrate the company’s global reach but also validate the trust placed in its

technical expertise and manufacturing excellence.

Understanding how pipeline materials behave in the presence of varying CO₂ stream compositions is

fundamental to the development of resilient and efficient CCS systems. The insights gained from this

testing campaign are expected to contribute to the broader adoption of CCS, supporting global

decarbonization targets and the transition to a low-carbon economy.

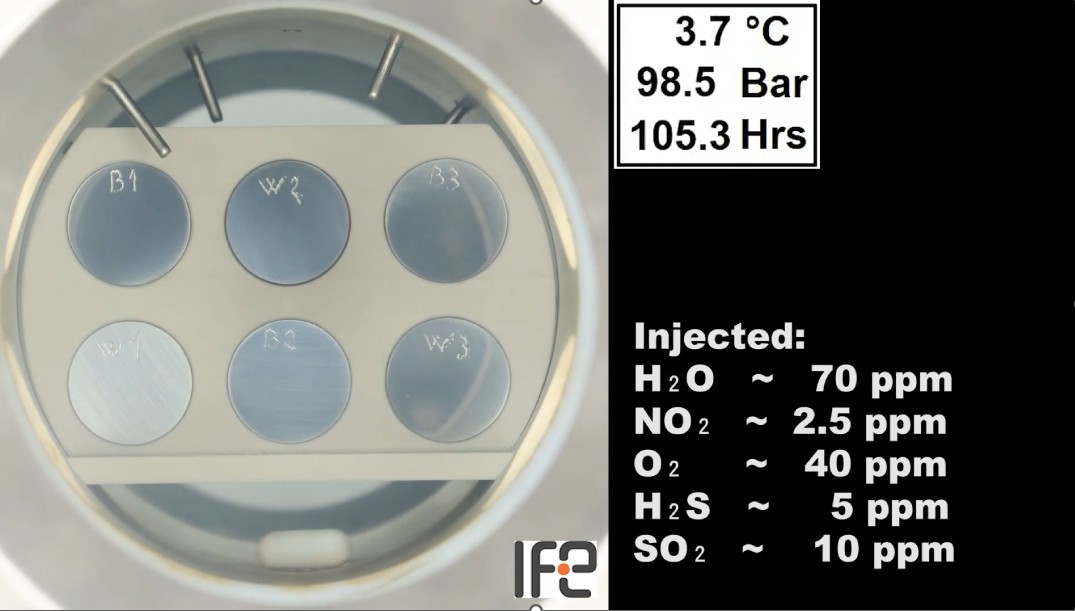

The ongoing program investigates both base metal and weld performance in simulated dense-phase CO₂ conditions, characterized by high pressure and low temperature. It further simulates real-world industrial environments by incorporating common impurities such as sulfur oxides (SOx), nitrogen oxides (NOx), hydrogen sulfide (H₂S), and methanol—substances known to affect corrosion behavior.

Preliminary findings confirm the strength and durability of Corinth Pipeworks’ pipeline solutions, validating their suitability for demanding CCS applications across diverse operational settings.

Additional testing is scheduled throughout 2025, reinforcing Corinth Pipeworks’ dedication to continuous improvement and leadership in CCS pipeline technology. These efforts align with the company’s broader sustainability vision and its proactive role in supporting a cleaner energy future.

About Corinth Pipeworks

Corinth Pipeworks (CPW), steel pipe segment of Cenergy Holdings, is a leading steel pipe manufacturer for the global energy and construction sector. With projects executed in more than 50 countries worldwide, we develop valuable solutions, exceed our customers’ expectations whether the application is a challenging offshore subsea flow line, a high criticality onshore gas transmission pipeline, transportation of 100% hydrogen at high pressures through large diameter/high strength steel pipelines, or a specialized structural steel requirement. All this by combining experience, on time delivery, innovation and investments in the latest technology. For more information about our company, please visit our website at www.cpw.gr

About IFE

The Institute for Energy Technology (IFE) is a leading energy research organization in Norway. Their high-pressure CO₂ flow loop offers unique capabilities for testing and validation under real-world CCS conditions. For more information about our company, please visit https://ife.no/en/about-ife/